HEL-X Flake 30 and Hel-X Flake Pro

Ideal for heavily polluted wastewater and compact systems

Due to the high porosity, Hel-X Flake 30 and Hel-X Flake Pro provide an extremely large inner surface area for growth of biomass. This allows very high removal rates even for small tank volume.

Inside the pores of the Hel-X-Flake 30 and Hel-X Flake Pro the biomass is protected from shearing forces. At the same time, the surface of the chip is cleaned to ensure high mass transfer rates of oxygen and nutrients.

Development

Hel-X biocarriers in biofilm processes and mass transfer processes

The success of conventional carriers for use in MBBR or IFAS allowed other applications to be investigated. High concentrations of BOD and COD need to be reduced in many industrial applications created the demand of larger active surfaces for carriers. To meet the needs of our customers, the development of the high-performance Hel-X Flake carriers started more than 15 years ago.

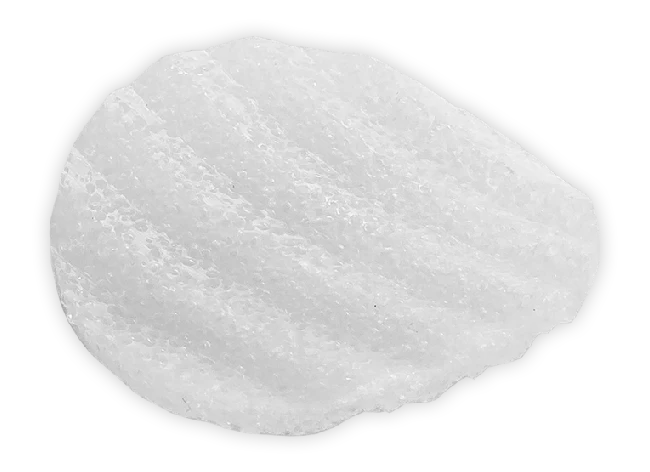

The high-performance carriers Hel-X Flake 30 and Hel-X Flake Pro are made of HDPE just as the conventional Hel-X carriers. However, the active surface results from a special pore structure of the plastic body.

Microorganisms grow inside the pore volume. Nutrients and oxygen are provided by mass transfer to the carrier surface and diffusion inside the pore volume.

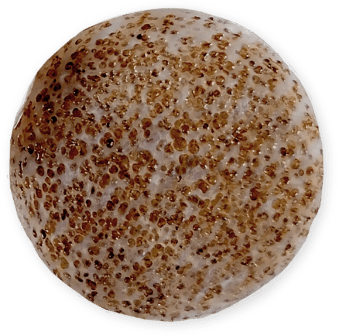

The Hel-X Flake Pro is a recent development. This carrier is no longer flat but has a special wave profile. This shape reduces the contact area between the individual Hel-X Flakes and as well to other surfaces resulting in optimal fluidization of the high-performance carriers. In addition, the wave structure provides an enlarged active surface for growth with microorganisms.

The Hel-X Flake PRO is protected by patents.

The HEL-X Flake 30 has been in production since 2019. With a diameter of 30 mm, this is significantly larger. It is characterized by its flat structure with a thickness of 1.1 mm.

The HEL-X Flake Pro has been in production since 2022. Due to the profiled shape, the Flake Pro has a significantly larger surface.

Technical data

The specific surface was confirmed by measurements at well-known universities and research institutions.

In order to ensure the constant quality of the flakes high-performance biocarrier, we prefer to use virgin material HDPE white.

| Diameter: | approx. 30 mm |

| Specific surface: | > 5.000 m² / m³ |

| Thickness: | 1,1 mm |

| Packaging: | 3 m³ big bags |

| Material: | HDPE |

HEL-X Flake PRO

| Diameter: | approx. 30 mm |

| Specific surface: | > 5.500 m² / m³ |

| Thickness: | 1,2 mm |

| Packaging: | 3 m³ big bags |

| Material: | HDPE |

application

The optimal solution for heavily polluted wastewater or for applications that require a compact construction.

Unique features of Hel-X Flake 30 and Hel-X Flake Pro feature is the internal pore structure with extremely large surface area for growth of biomass in combination with large surface area for mass transfer realized by the disc or wave geometry.

Hel-X Flakes are the optimal solution for applications that require a compact design and for treatment of heavily polluted industrial wastewater.

Municipal wastewater treatment

- COD / BOD – Elimination

- nitrification / denitrification

- Compact sewage treatment plants / container sewage treatment plants

- sludge water treatment

Industrial sewage

- paper and pulp industry

- Food industry

- Steel industry / coking plant

- petrochemicals

- Chemical industry

Aquaculture

- Fish farming

- recirculation systems

- koi farming

Advantages

- Very large specific surface area for colonization with biomass

- The biomass is protected in the pores.

- Thin disc or wave shape for optimal supply of oxygen and nutrients

- Large diameter for easy retention in tanks and basins

Service

We would be happy to advise you

Hel-X products cover the entire spectrum of conventional and high-performance carriers.

Our product specialists are available for any questions on selection of carriers, delivery times and logistics.

With our partners, we can support for the design and procurement of aeration systems, retaining systems or mixers.

Quality control

Quality control in production ensures a consistently high level of product quality for your application in terms of size, density and pore structure.

Our Hel-X biocarrier are DIN EN ISO 9001:2015 certified.